Freight Flexibility to Help You Control Costs

Freight and fuel charges are a constant challenge to steel users. Many get locked into supply contracts where these factors put them at a disadvantage. We may hold the key to help you unlock that problem.

Road, Rail and Barge

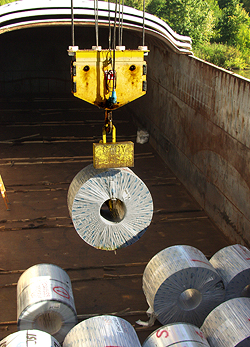

We offer the ultimate in flexibility, accepting steel coils from around the world into our climate-controlled storage without ever touching a truck. Barge shipments from the Port of New Orleans or the mills of Gary/Burns Harbor, Pittsburgh, Alabama and Mississippi are unloaded by a 50-ton crane right into our building. Rail shipments, arriving via our dedicated spur on the CN system, are unloaded the same way.

But if truck is the mode of choice, it's good to know that we are near the crossroads of four major interstates. Our strategic location near St. Louis is a short haul from the mills of Granite City and within an 8-hour drive of over 50% of the country's steel making capacity.

Material Delivery Specifications

The table below provides specifications for material to be unloaded at TMW.

Print a copy for use in your planning.

|

TMW Material Unloading Specifications |

||||

|

*** All material returned to TMW must be safely, securely banded *** |

||||

|

*** All return material must be accompanied by a Material Return Authorization Form, |

||||

|

Plant #1 |

||||

|

North Side (truck only) |

South Side (rail, barge, truck) |

|||

|

Coils |

||||

|

Unload Method |

Coil Grab (must have 16" |

C-Hook (max 80" full toe) |

||

|

Max. Weight |

55,000 lbs |

80,000 lbs |

||

|

Min. Inside Diameter |

20" |

20" |

||

|

Max. Outside Diameter |

84" |

84" |

||

|

Max. Width |

74" |

74" |

||

|

Mults (banded together) |

None (transfer to South Side) |

74" CTL or 80" (coil to coil) |

||

|

Skidded Coils |

||||

|

Fork Rear |

10,500 lbs. Max |

|||

|

Fork Side |

9,000 lbs. Max |

|||

|

Sheet Lifter |

Coil Width 42" Max. / 12,000 lbs. Max. |

|||

|

Sheets |

||||

|

Fork Lift |

||||

|

Fork Rear |

10,500 lbs. Max |

|||

|

Fork Side |

9,000 lbs. Max |

|||

|

Sheet Lifter |

||||

|

Max. Weight |

35,000 lbs. |

|||

|

Max. Weight |

15,000 lbs. |

|||

|

Max. Width |

74" |

|||

|

Max. Length |

480" |

|||

|

*** When using the 40 ft. extensions: 15,000 lb. max lift or 1 stack maximum *** |

||||

|

Plant #2 |

||||

|

Coils |

||||

|

Unload Method |

C-Hook (max 80" full toe) |

|||

|

Max. Weight |

75,000 lbs |

|||

|

Min. Inside Diameter |

24" |

|||

|

Max. Outside Diameter |

84" |

|||

|

Max. Width |

74" |

|||

|

Skidded Coils |

||||

|

Fork Rear |

12,000 lbs. Max |

|||

|

Fork Side |

12,000 lbs. Max |

|||

|

*** NOTE: Sheets CANNOT be Unloaded at Plant 2*** |

||||